We have produced parts for various industries such as Marine, Automotive, Industrial, Recreational, Aviation/Aerospace, etc.

We have dealt with part complexity ranging from very simple to extremely complex projects requiring vast experience with closed molding and advanced tooling.

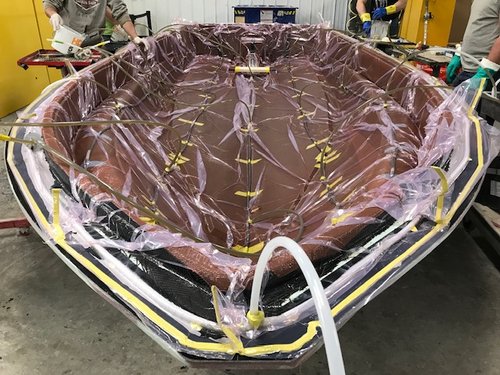

Master Composites, Inc. specializes in all forms of closed molding production. We produce parts for many different industries, all requiring a tailored laminate specification for their needs. The uniqueness of closed molding vs open molding is that we can choose from hundreds of reinforcement and resin-type variations. With our advanced knowledge in this field, we pinpoint the physical and mechanical features that you are looking for out of your parts.

The key feature in closed molding vs. open molding, is resin to glass ratios. Compared to open molding, where glass content hovers around 30%, closed molding can yield as high as 70% glass content and produce a very lightweight, high-strength composite that is unachievable in open molding. This important feature allows us to tailor any composite to a polyester, vinyl ester, or epoxy resin system matched with any reinforcement type you choose. Eglass, Carbon, Aramid, Basalt, and Inegra are some examples of reinforcements we use here daily.

In the closed molding world, Master Composites, Inc. uses CCBM, VARTM, and LRTM as our production methods of choice. There are more processes in closed molding, but we specialize in these three processes because we can produce virtually any composite from them more rapidly, precisely, and cost-effectively than open molding.

It all gets done here!

We know how to produce the exact part you are looking for!